Mercedes panel sectioning is a specialized repair technique for precise disassembly and reassembly of car body sections, like doors or fenders, to restore structural integrity and visual appeal with high-quality paint services, minimizing waste and turnaround time compared to full-body replacements.

Uncover the intricate world of Mercedes panel sectioning, a precision engineering marvel. This innovative process involves dividing vehicle bodies into distinct sections for efficient manufacturing and repair.

Our article breaks down the fundamentals, walks you through every step, and explores the multifaceted benefits and use cases of this technique. From enhanced productivity to tailored customization, understanding Mercedes panel sectioning offers valuable insights into modern automotive craftsmanship.

- Unveiling Mercedes Panel Sectioning Basics

- The Process: From Start to Finish

- Benefits and Applications of Panel Sectioning

Unveiling Mercedes Panel Sectioning Basics

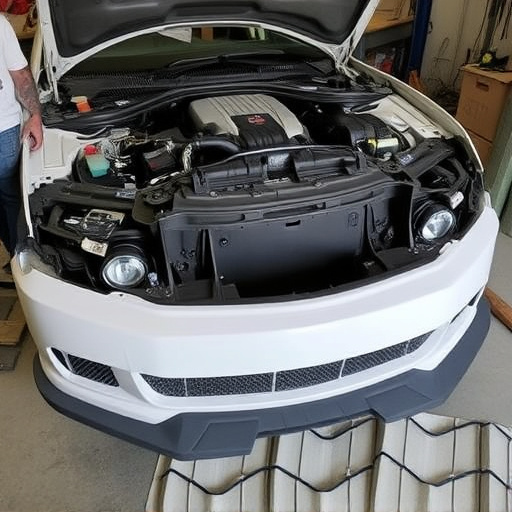

Mercedes panel sectioning is a meticulous process that involves breaking down a vehicle’s body into smaller sections for easier repair and replacement. This advanced technique is a cornerstone of high-quality car paint services, ensuring precision and efficiency in automotive restoration. By isolating specific panels, such as doors, fenders, or bonnets, technicians can address damage or wear individually, resulting in exceptional repair outcomes.

The process begins with meticulous disassembly, where skilled technicians carefully separate the panels from the main body structure. This enables them to inspect each section for any signs of damage, corrosion, or defects. Once identified, these issues are addressed using top-notch car paint services and precision tools, ensuring a seamless blend between the original and repaired sections. The result is not just a visually restored car but also one with enhanced structural integrity, thanks to meticulous automotive restoration techniques.

The Process: From Start to Finish

The Mercedes panel sectioning process is a meticulous art that forms a crucial step in premium car body repair, particularly for iconic vehicles like Mercedes-Benz models. It begins with the disassembly of the affected vehicle components, where skilled technicians carefully separate the damaged panels from the rest of the car body using specialized tools. This initial phase demands precision to avoid damaging surrounding parts. Once removed, each panel is meticulously examined for any defects or misalignments, ensuring that only pristine sections are selected for reconstruction.

The heart of the process lies in the sectioning itself, where the damaged area is precisely cut and separated from the intact panels. This meticulous cutting ensures a clean break, allowing for accurate measurement and replacement. Skilled artisans then prepare these sections, often through processes like grinding or sanding, to create a seamless fit when reassembled. The end goal is flawless integration, maintaining the vehicle’s original aesthetics and structural integrity, which is essential in automotive collision repair.

Benefits and Applications of Panel Sectioning

Mercedes panel sectioning is a precision technique used to separate and repair specific sections of a vehicle’s body, offering several advantages for auto body shops and their customers. This method allows for more targeted and cost-effective repairs, especially in complex cases where only certain panels are damaged. By isolating the affected areas, the process minimizes the impact on surrounding unharmed components, leading to faster turnaround times compared to traditional full-body replacements.

The application of Mercedes panel sectioning is vast within the auto body shop industry. It caters to various scenarios, from minor fender benders to significant collision damage. This versatile approach ensures that vehicle bodies can be restored to their pre-incident condition, maintaining structural integrity and aesthetic appeal. Moreover, it reduces waste by minimizing the need for excessive material replacement, making it an environmentally friendly choice for both body shop services and vehicle owners.

Mercedes panel sectioning is a sophisticated manufacturing process that offers numerous advantages for vehicle production. By understanding these basics, we can appreciate how this method enhances efficiency, precision, and customization in automotive assembly. Whether it’s for repairs or innovative design choices, Mercedes panel sectioning plays a pivotal role in shaping modern vehicles. This technique ensures that each component is meticulously crafted, contributing to the overall quality and performance of Mercedes-branded cars.